On Monday The English Apple Man attended a Sprayer Workshop at Brogdale Farm organised by FAST Ltd and presented by Dr.Andrew J. Landers from Cornell University in New York State USA.

Controlling pest and disease is critical to supplying quality home grown apples & pears at an affordable price for UK consumers. The necessity of spraying pesticides in orchards to control pest & disease may not be fully appreciated by some consumers, but with no controls the quality and yield would be decimated.

Ah, you might argue but organic overcomes the need for pesticides!

Well, actually NO!

Organic production cannot be effectively managed in our climate without spraying regularly with organically approved materials. Copper & Sulphur have been at the heart of Scab and Mildew control in organic orchards. Pests are increasingly being controlled with predators in conventional and organic orchards.

Whether Organic or Conventional the spray needs to be delivered safely and efficiently; operator safety, environmental safety, consumer safety all play an integral role in calibrating the sprayer; pesticide application efficacy is critical and key factors are water droplet size, air volume rather than air speed and forward tractor speed.

Effective Orchard Spraying - A Practical Guide for Growers

Dr. Andrew Landers is an English Man who studied agriculture at the Royal Agricultural College, Cirencester where he obtained his Diploma of Membership of the Royal Agricultural College. Andrew obtained his masters degree in agricultural engineering at Silsoe College, Cranfield University and his Ph.D at the University of Bath.

Dr. Andrew Landers is an English Man who studied agriculture at the Royal Agricultural College, Cirencester where he obtained his Diploma of Membership of the Royal Agricultural College. Andrew obtained his masters degree in agricultural engineering at Silsoe College, Cranfield University and his Ph.D at the University of Bath.

Andrew has led a distinguished career in research and teaching including head of agricultural engineering at Harper Adams University. He is a Chartered Engineer, Chartered Environmentalist, a Member of the American Society of Agricultural and Biological Engineers........far too many more accolades to mention, but clearly a global expert on all aspects of sprayer technology and techniques.

Today Andrew directs the application technology programme at Cornell University where his appointment involves the use of engineering solutions to provide more effective and safer spraying of fruit and vegetable crops.

The Sprayer Workshop included an in depth presentation of facts critical to effective orchard spraying, all of which can be found in Andrew Landers excellent new book which was integral to the course and well worth purchasing by any professional fruit grower. To order click on Effective Orchard Spraying

Below: Andrew Landers (fourth from right) with course members - James Shillitoe who organised the event is on the extreme left of picture.

Calibration

Integral to the workshop; Airflow adjustment, nozzle orientation, methods of quantifying deposition, maintenance and sprayer adjustments, drift reduction methods based on trials at Cornell University, good management of the spraying operation to maintain timeliness, selecting sprayers, and getting the most from the spraying operation.

Andrew emphasized the importance of a correctly calibrated sprayer and demonstrated some of the options now available for speeding up the accurate calibration of individual spray nozzles.

Below: Old style pipe system - New style pipe system - and Digital calibrating tool for faster calibration

When calibrating the sprayer, an essential element involves ensuring each nozzle delivers the required amount of spray. To calibrate a pipe is placed over the nozzle and the water (spray) collected in a jug; measuring the flow over one minute.

When calibrating the sprayer, an essential element involves ensuring each nozzle delivers the required amount of spray. To calibrate a pipe is placed over the nozzle and the water (spray) collected in a jug; measuring the flow over one minute.

Andrew demonstrated a simpler way of carrying out this calibration exercise - the first task is to secure the collection pipe; in the old system it was held in place by tightening up a jubilee clip - 'slow and tediuous' - the device demonstrated by Andrew uses a 'claw' fitting to hold the pipe in place; 'much quicker' - the second device speeds up the measuring (calibrating) process, avoiding the tedious task measuring the flow into a jug, the use of a flow device which automatically signals digitally the flow rate in far less time is a 'mega step forward'

Next a look at different nozzle types used in the past and still in some parts of the World.

Basically Nozzles break liquid into droplets; 300+ micron nozzles deliver a coarse droplet - 150- micron nozzles deliver a fine droplet - using 'hollow cone nozzles creates a fine droplet size at normal operating pressures e.g. 80 - 135 psi.

Nozzles deliver liquid flow and AIR carries the liquid (in correct droplet size) to the tree target.

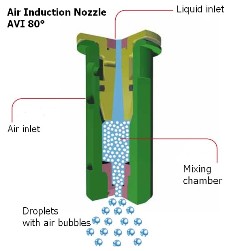

Below: Left - hollow cone nozzles - and - Right - Air induction nozzles

Ceramic disc (pretty much old technology) - Hollow cone nozzles deliver fine droplets - Air induction nozzles deliver coarse droplets. The use of hollow cone and air induction nozzles in different parts of the 'air outlets' can deliver ideal droplets at point of target without causing unnecessary 'drift' by arranging the air induction nozzles on the higher positions drift is reduced.

Ceramic disc (pretty much old technology) - Hollow cone nozzles deliver fine droplets - Air induction nozzles deliver coarse droplets. The use of hollow cone and air induction nozzles in different parts of the 'air outlets' can deliver ideal droplets at point of target without causing unnecessary 'drift' by arranging the air induction nozzles on the higher positions drift is reduced.

The Venturi air induction nozzle draws air into a mixing chamber making bubbles within the liquid delivering a coarser droplet size than the hollow cone nozzle.

Below: Albuz 80 air induction nozzle illustration

Venturi nozzles have a pre-orifice to reduce pressure inside the nozzle: they are also called Air Induction Nozzles.

Venturi nozzles have a pre-orifice to reduce pressure inside the nozzle: they are also called Air Induction Nozzles.

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe. The Venturi effect is named after Giovanni Battista Venturi, an Italian physicist.

An internal venturi creates a vacuum inside the nozzle body and air is drawn into the nozzle through one or two holes in the nozzle side, mixing with the spray liquid stream as it passes by.

Large air-filled droplets are created : the emitted spray contains large droplets (approximately 375 microns) filled with air bubbles and virtually no fine, drift-prone droplets.

Into the orchard

Moving from the 'classroom' to the field, Andrew explained the virtues and drawbacks of the different sprayers on site; 'piston pump v diaphragm pumps' - and much more - far too much to include in this Journal!

However, the next steps after ensuring the sprayer is calibrated is making sure the air flow from the sprayer is of the right volume and direction.

Below: a typical orchard sprayer with a tower sufficient to carry the air up and into the tree canopy, without spiraling out of control and causing drift - and - Andrew explaining air movement

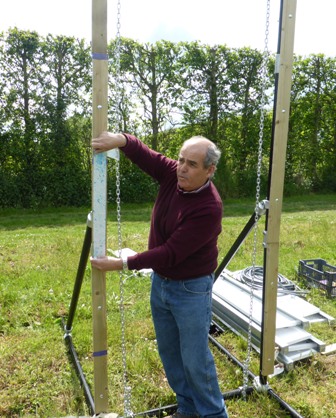

The next step is to check efficacy of the spray coverage on the target (tree) which can be done with a simple test rig before more precise measurements in the orchard itself.

The test rig is a simple structure, easily made with 'special marker paper' placed at different heights - the paper marker identifies each spot where water (spray) has landed by turning blue......

Below: Andrew with the test rig - and - A Sprayer driven past the test rig

Below: Spray deposition is clearly shown by the blue spots on the marker paper

The test rig can also be used to measure the quantity of spray delivered at each height by placing a 'catch tray' onto the chains (part of the rig) - The final step in determining the efficacy of spray deposition in the actual orchard can be measured by using a coloured dye in the spray tank and inspecting the level of dye on the leaves after the sprayer has passed through some monitor rows.

Below: Left - Andrew Landers and the 'catch tray' - and - Right Andrew with a sample of the dye

The Sprayer Workshop was excellent and I would highly recommend any professional grower and/or farm staff to attend one of Dr.Andrew Landers courses; he is without doubt one of the world's leading experts on effective use of sprayer technology and a most charismatic tutor....

Finally; The English Apple Man enjoyed an hour (or two) in an Organic Cider Apple Orchard on Thursday afternoon.

Below: The blossom was beautiful, the aroma breathtaking and the bees were very, very busy!!!!!!

That is all for this week - sorry for the delay, but I hope my readers - 'professional and amateur' found the content useful

Take care

The English Apple Man