By the end of next week many growers will be picking Cox and Gala for 'long term storage'

What do we mean by long term?

The practice of storing apples until February/March was how we labelled, long term for many years.

As storage science improved, Cox crept into April and for marketing purposes that was ideal, with the arrival of Cox from New Zealand, followed by NZ Gala soon after.

British Gala was not considered suitable for marketing much beyond February in the early years of 'home grown' production, but as volumes built up and nutritional and storage sciences developed, Gala has been stored and marketed into early summer May/June.

British Gala was not considered suitable for marketing much beyond February in the early years of 'home grown' production, but as volumes built up and nutritional and storage sciences developed, Gala has been stored and marketed into early summer May/June.

Over the course of the last 2-3 years with the aid of DCA (Dynamic Controlled Atmosphere) storage and a better selection of fruit with the optimum 'dry matter content' - storage potential has extended, British Gala has been successfully stored into August when the first of home grown 'New Season' apples become available.

This week The English Apple Man looks at trials carried out by Nigel Jenner, Chief Technical Officer for Avalon Produce Ltd into sophisticated, controlled atmosphere apple storage.

For many years the 'Blue Riband' of storage technology (certainly for Cox apples) was C/A (Controlled Atmosphere) with low oxygen at circa 1.2% and C02 at less than 1%.

Traditional long term C/A storage, relies on the use of 'researched' regimes to ensure each variety is kept in a storage regime using pre-set levels of; 1) Temperature. 2) Oxygen. 3) Carbon Dioxide.

Dynamic Controlled Atmosphere

In the UK two DCA systems are in operation - SAFEPOD and HARVESTWATCH

Dynamic Controlled Atmosphere - HARVEST WATCH

Dynamic Controlled Atmosphere - HARVEST WATCH

While visiting the many stands at Interpoma in 2012, The English Apple Man spent a very interesting and productive 'half hour' talking to a storage expert about Dynamic Controlled Atmosphere (DCA) storage.

In Harvest Watch the Fluorescence detection units are placed within the store detecting the change in fruit condition allowing accurate monitoring of the fruit condition and adjustment to the level of Oxygen in the store; Oxygen can be kept at levels of 0.2 - 0.3% delivering superior storage life in comparison to traditional C/A stores where Oxygen levels are kept at (circa) 1-1.2% depending on variety.

The Storage of Apples & Pears is a vital part of the seasonal supply; without the sophisticated storage used by our growers, the eating quality would be far below the standard we enjoy today. 'Dynamic Controlled Atmosphere (DCA) Storage' is the leading C/A system globally.

Nigel's trial is based on SAFEPOD technology

SAFEPOD is a DCA system used to measure Respiratory quotient (RQ) within a sample chamber.

SAFEPOD is a DCA system used to measure Respiratory quotient (RQ) within a sample chamber.

The Safepod sits in the CA room and shares the temperature and atmosphere of the complete room.

Periodically the valves are shut and the respiration and RQ is measured as an indication of fruit condition.

Safepod was developed by David Bishop and Jim Schaefer of Storage Control Systems (SCS)

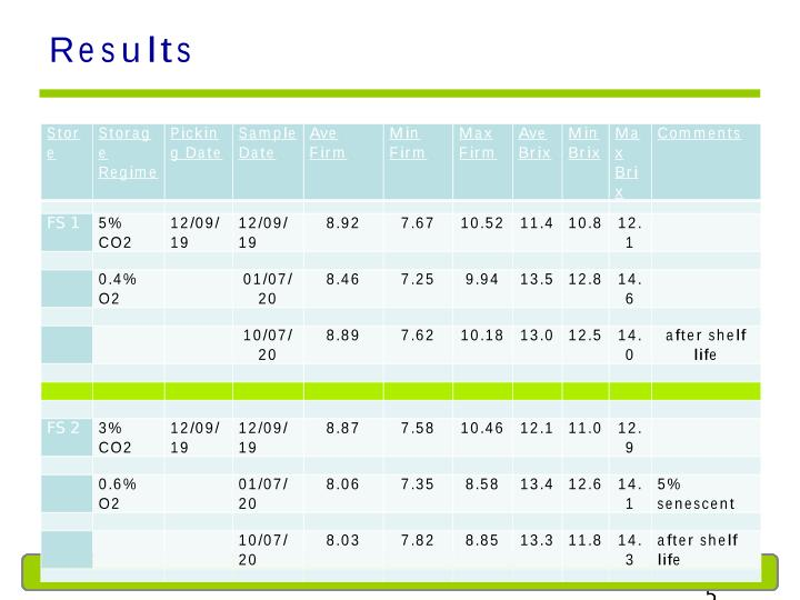

Nigel Jenner has been trialling the Safe Pod technology with Mini Pods to determine the influence of higher C02 on fruit quality

Nigel said: "we have these Mini Pods at our offices, which are scaled down versions of the Safe Pods which some of our growers have already, and I was asked by colleagues if I would trial taking Gala into July assessing the quality of the apples after circa 10 months in store.

Nigel commented "we are getting some Lab Pods which are slightly bigger and capable of holding more fruit for future trials"

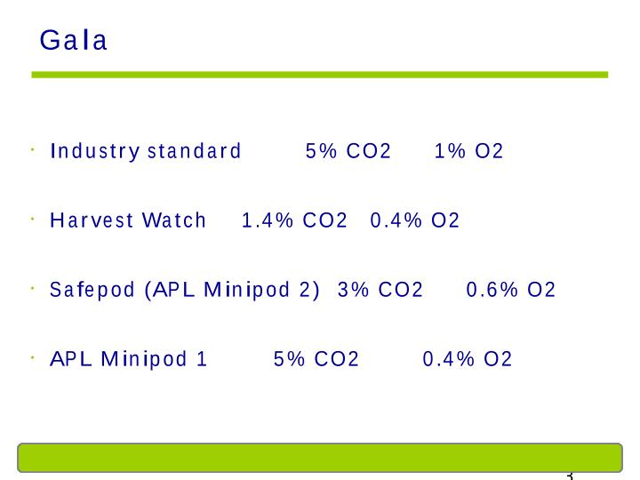

Nigel continued: "As you all know, the industry C/A standard for Gala is 5% C02 and 1% O2.

Then there is Harvest Watch, an Italian system which recommends storing Gala at 1.4 CO2 and 0.4% O2.

The SAFEPOD standard used by UK growers is 3% O2 & 0.6% O2.

Nigel is trialling:

Safepod (APL Mini Pod 2). 3% C02 - and 0.6% O2 (standard regime)

Safepod (APL Mini Pod 1) 5% C02 and 0.4% O2 (experimental regime)

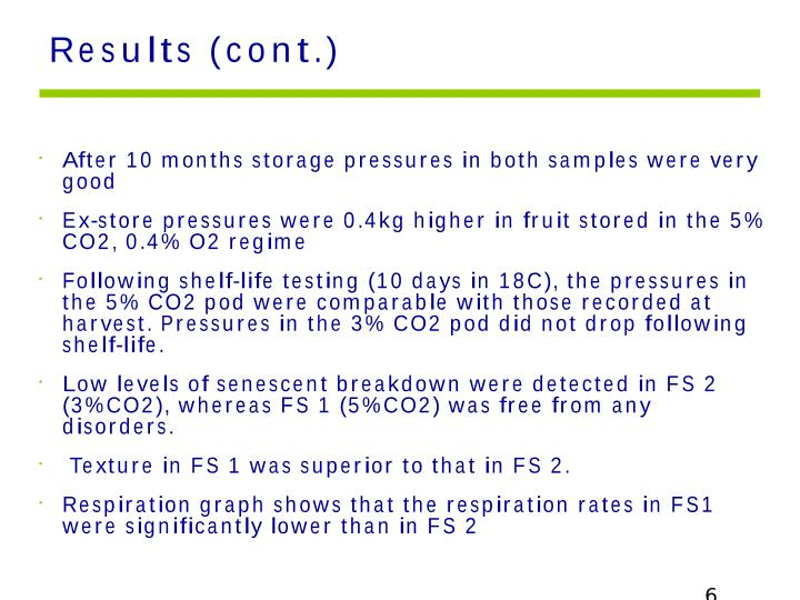

The key element for the storage trial is: 5% C02 which once trials endorse as safe (no internal damage) should allow Gala to be kept confidently into July/August while delivering excellent texture and flavour!

Endorsement!

Nigel Jenner took some of these apples from the 5% C02 / 0.4% O2 regime and gave them to a couple of growers to try, not telling them they were 10 months old. They tasted the Gala and exclaimed; "where did you get new season Gala this early?

Comment: The English Apple Man reviews storage technology

Apple storage regimes - background information

Traditional long term storage, relies on the use of 'researched' regimes to ensure each variety is kept in a storage regime using pre-set levels of; 1) Temperature. 2) Oxygen. 3) Carbon Dioxide.

Temperature. Each variety needs to be stored at a temperature specific to that variety; while some can be stored at 1 degree C, others will develop internal disorders if kept for a longer term in that regime.

Oxygen. For successful long term storage the Oxygen available to the fruit in store should be just enough to allow the fruit to 'stay alive' that is to say, by depriving the fruit of oxygen we can slow the respiration of the apple down to a level where the fruit is just breathing. This keeps the fruit in 'tip top' condition for several months (depending on variety) however if the oxygen level drops too low, the process of fermentation begins and the fruit will become alcoholic, resulting in total loss of the fruit for any useful purpose.

Carbon Dioxide. The level of C02 inside the store has a critical part to play in the success of fruit in long term storage, for as the Oxygen level drops, the C02 level rises. For many varieties; Cox for instance, the level must remain below 1% or internal disorders (browning) will develop. But other varieties; Bramley for instance, require higher levels of C02 to keep the green background colour; starved of C02 a Bramley will go yellow in store. Excess C02 can be removed from the store environment by using lime or carbon scrubbers to 'adsorb' the excess C02.

SO, having set the regime; Temperature + Oxygen + C02 to the required level for the variety in store, we monitor and manage the conditions by various strategies.

Temperature is controlled by temperature readings from in store probes.

Oxygen & C02 readings taken by an O2 & C02 analysers which sample the store air on an hourly basis.

The readings are fed back to a computer control system which follows the pre-set programme and keeps the fruit in the appropriate regime.

DYNAMIC CA Storage is quite different; instead of setting the regime within the known parameters (safe conditions) DCA monitors the performance of the fruit and responds accordingly.

The monitors; fluorescence interactive response monitor; are connected to a computer control system and the operator adjusts oxygen levels in response to any fluctuations in the fluorescence signals. This system monitors the chlorophyl levels in the fruit by measuring the change in the green colour of the apple in the monitor boxes.

This is one type of DCA technology that is being marketed and used commercially. However, it is not the only way to utilize lower oxygen levelsf or programmable CA storage.

The use of low oxygen by measuring the alcohol content of apples and adjusting the oxygen level accordingly is another.

Either way, the system of monitoring the fruit and reacting to the status is 'the way forward' for long term storage.

The potential gain is not just an ability to ensure the fruit stores in prime condition for a longer period, but one in which the moisture loss is significantly reduced; both the consumer and grower benefit; the consumer will enjoy an apple with a superior texture and the grower will benefit from a reduction in weight loss. This is a significant gain for both!

In general, the lower the oxygen concentration, the longer the fruit can be stored. There is, however, a lower limit in terms of oxygen concentration, at which point fermentation will commence; this can reduce the quality of the fruit (and its shelf life, as a result). This is why in conventional C/A stores 'safe' O2 concentrations, i.e. usually slightly over 1%, is used for storage.

Dynamic CA storage means that the fruit is automatically stored at optimum conditions which are constantly adjusted on the basis of the fruit's respiratory activity. Oxygen percentages of less than 1% are no problem because the oxygen concentration will be immediately amended if it threatens to get too low.

Asking the question? If we use lower O2 storage, why would we want to use Dynamic CA technology?

Lowest safe oxygen concentration changes with the 'Climatic conditions, seasonal factors, orchard characteristics and harvest maturity.

The Technologies available or being tested for Dynamic CA include - Ethanol production by fruit Respiratory quotient (indicating switch to anaerobic respiration) and Chlorophyll fluorescence.

Low O2 limit (LOL) Below this fruit will be damaged; At low O2 fruit switches from aerobic to anaerobic respiration. and CO2 production rate increases.

Respiratory quotient = CO2 production/O2 uptake Increases below LOL Fermentation threshold (Ethanol production) higher than LOL

An increase in chlorophyll fluorescence signal is an (indirect) indicator of low oxygen stress in apples. RQ increase correlates with the chlorophyll fluorescence response.

Chlorophyll fluorescence is a tool for studying mechanisms of photosynthesis used since the 1970's. The standard technique for assessing crop health (rate of photosynthesis)

Chlorophyll fluorescence is the standard technique for assessment of levels of pollution in fresh water (photosynthetic rate of algae)

Chlorophyll fluorescence has been investigated as a post-harvest tool since late 1980's (harvest maturity, senescence, stress)

Plants use energy from the sun in tiny energy factories called chloroplasts. Using chlorophyll in the process called photosynthesis, they convert the sun's energy into storable form in ordered sugar molecules such as glucose. In this way, carbon dioxide from the air and water from the soil in a more disordered state are combined to form the more ordered sugar molecules.

Chloroplasts are highly dynamic, they circulate and are moved around within plant cells, and occasionally pinch in two to reproduce.

Chlorophyll fluorescence for assessment of low oxygen stress in fruit; how does it work?

When photosynthesis is efficient fluorescence is low, but if chloroplasts are stressed (by low oxygen) they become less efficient and fluorescence increases.

Fluorescence gives off Heat; Chloroplasts are only in the skin of the apple and apples retain functional chloroplasts even after months of storage in the dark.

2020 harvest update

Cox picking for long term storage (March/April) should begin on most sites next week (w/c 31st August). Generally, pressures and brix are very good this year, which bodes very well for eating quality but as with the Conference, starch levels are being maintained by recent rainfall and are likely to fall rapidly next week.

Cox picking for long term storage (March/April) should begin on most sites next week (w/c 31st August). Generally, pressures and brix are very good this year, which bodes very well for eating quality but as with the Conference, starch levels are being maintained by recent rainfall and are likely to fall rapidly next week.

Colour on Cox is generally good and will improve further with some colder nights forecast over the next week.

In most Cox samples we are seeing approximately 10%-15% of the fruit affected by water core. This fruit will turn alcoholic and rot if stored in ultra-low oxygen conditions. Therefore, it is strongly recommended that any fruit stored in low oxygen is stored in a regime of 2% O2, <1% CO2 until store monitoring has confirmed this disorder is no longer present.

Gala On all sites, starch degradation has started in several apples, but many are still 100% black. Picking should begin when the starch has started to move in all the apples and ideally, fruit picked for long term DCA storage should be picked before the starch has declined to 80%.

Gala On all sites, starch degradation has started in several apples, but many are still 100% black. Picking should begin when the starch has started to move in all the apples and ideally, fruit picked for long term DCA storage should be picked before the starch has declined to 80%.

For long term ULO storage this should be before starch has declined to 70%. Typically the initial decline is very slow, before increasing rapidly to around 4%/day. This rapid decline is predicted to occur at the end of next week/beginning of W/C 7th September and will be confirmed in next week's newsletter.

Gala status 96% starch

That is all for this week

Take care

The English Apple Man