Over the last 60 years, The English Apple Man has been involved with the annual apple harvest.

The first as a teenager 'just out of school' in 1958!

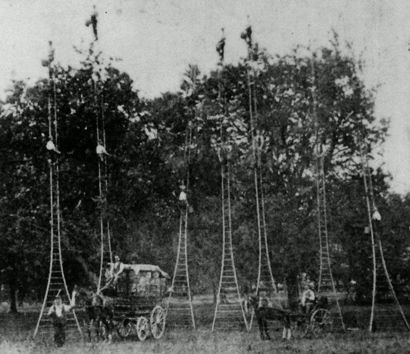

In those far off 'halcyon days' when trees were much, much bigger, some 25ft tall, wooden ladders were integral to the mode of picking.

We picked in those days with a canvas bag on our back, placing the picked fruit into the bag carefully to avoid bruising. The system was tiring and required great care. Once the bag was full, we would make our way to empty the bag, using our hands/arms to keep the bag clear of our body, or damage could/would occur!

The next task, emptying the contents of the bag (20-30lb of fruit) into boxes without damaging them!

The next task, emptying the contents of the bag (20-30lb of fruit) into boxes without damaging them!

The process meant we spent a large amount of time moving ladders, climbing 'up & down' ladders and walking carefully from tree to boxes before emptying with great care e.g. 'slowly'

Below: left; These are cherry picking ladders, but demonstrate the difference from the 1920's to today and right, a Bush tree (apples) post war and 1950's / 1960's which would still have required ladders of 18-20 rungs!

By the 1970's forward thinking growers were discarding boxes for harvest, moving onto the 'bulk bin' - still the mode of harvest and storage today.

Apples were still picked by hand, but by then into cushioned picking buckets worn in front of the body - a big improvement - still opportunities for pickers to bruise fruit, but a much kinder system for picker and apples!

Today most orchards have slender 'hedgerow systems'

Below: The next step saw Picking Trains transporting the bulk bins down the rows allowing the picker a shorter distance between the tree and the bin. Some large growers used picking trains to clear the lower part of trees and harvesting platforms to clear the tops section.

The Pluk-O-Trak harvester has been used on the continent for many years and a few UK growers moved to that system in recent years.

The Pluk-O-Trak harvester has been used on the continent for many years and a few UK growers moved to that system in recent years.

Pluk-O-Trak: the versatile harvester

The Pluk-O-Trak is a versatile harvest aid for picking mainly apples, pears, peaches, nectarines, plums and oranges. Fifty years of development and innovation ensured that the Pluk-O-Trak is now used worldwide for the efficient and labour-saving organisation of the harvest.

The English Apple Man wrote about Richard Day's use of Pluk-O-Trak in last year's Journal edition of the Journal for 4th October 2019.

As the labour situation becomes more uncertain - Brexit will put the main source of harvest workers from Romania and Bulgaria in the same bracket as harvest workers currently outside the EU. This will then depend on HM Government sanctioning the recruitment of any workers from outside the UK.

Currently Government has allowed 2,500 from outside the EU under a trial period of the SAWS scheme during 2020 season. There has been talk of allowing 10,000 harvest workers to be licensed under SAWS for 2021, but with a national need for circa 80,000 workers in the produce industry, the prospect looks alarming at present for harvesting next year.

SAWS = Seasonal Agricultural Workers Scheme

The availability of hard working young people from overseas has been an integral element in the successful expansion of the British Top Fruit (apples & pears) and the Soft Fruit (Strawberries. Raspberries, Blackberries and Blueberries) over the last 10-20 years.

The current labour force (even from Romania & Bulgaria) are more mature (and 'by and large' not so energetic) which has encouraged growers to look at harvest machines to speed up the harvest performance.

One of our largest growers: Adrian Scripps Ltd has invested in six REVO PUMA harvest machines at their Parsonage Farm at Cobham in Kent. The production per head which has been averaging 5 bins per day on the previous system has now risen to 7 bins per head, per day!

The first video demonstrates Adrian Scripps growing and packing process for their main customer TESCO highlighting the partnership between grower and retailer.

Click on ADRIAN SCRIPPS - TESCO

The second video demonstrates how Adrian Scripps delivers the latest harvesting technology in 2020

Click on ADRIAN SCRIPPS HARVESTING 2020 with REVO PUMA harvesters

That is all for this week

Take care

The English Apple Man